The CBX1000 hails from an older line of GP 5 and 6 cylinder race engines that were designed by a young engineer by the name of Shiochiro Irimajiri. Irimajiri, in his early years at Honda, designed the infamous 250 CC and 297 CC 6 cylinder GP race engines, as well as the 23,000 rpm 50 cc twin, and the 125 cc 5 cylinder of the late '60's. These engines all kept with the traditional Honda theory: More RPM = More Power (to put it crudely). Irimajiri was designing these engines to compete against 4 cylinder two-stroke engines and cylinder multiplication was his competitive solution. As is life, all good things must come to an end... Or a brief pause.

The advancement for a Honda engineer back then was from racing to production. A young engineer would begin working on the GP engines while the more experienced engineers designed production vehicles for the worldwide market. After Irimajiri had designed a multitude of innovative GP engines in his 20's, he began working on production vehicles for Honda. During the 70's he, and other top engineers, worked on the CVCC engine and the Honda Civic. The market for small, efficient automobiles was increasing and Honda had to keep up with the competition. Once the Civic project was completed, Honda moved Irimajiri from their only R/D facility in Wako, to a new facility in Asaka. The motorcycle division was now in Asaka, and the automobile and power products division remained in Wako. Up until this point in 1974, Honda only had one research facility.

With the line of motorcycles produced by Honda becoming dated, it was necessary to create something new and appealing for a Go-fast market. Up on the drawing board were two engines, a 4 cylinder 1000 cc engine and a 6 cylinder 1047 cc engine. Both designs carried through for 6 months until it was decided that the 6 cylinder be used. This decision was made based on several attributes. 6 cylinders had been proven to give smoother power over a 4 cylinder and there is an incredible sound that can only be produced by a 6 cylinder. The longevity of a 6 cylinder over a 4 cylinder had also been proven by the experiences of the Project Leader, a 37 year old Shiochiro Irimajiri.

From the drawing board to production, the CBX1000 only took a year and a half. The research was already completed from thorough testing of the 5 and 6 cylinder engines of the 60's. 1978 debuted the first CBX1000 with 105 bhp and a quarter mile time of a reported 11.36 s.

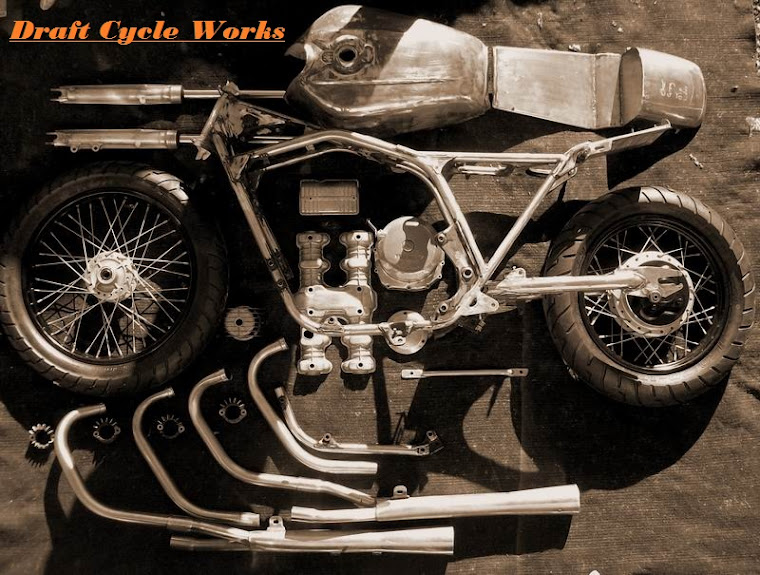

Now enough of my own historical babbling. I read the following article a while back and am still in aw over the attention to detail and the determination that is evident by simply viewing a few old grainy pictures. Jim hall took the legendary CBX1000 and turned it into a reliable land rocket.

I have taken this article from the CBX Club website and it is originally from the November 1989 issue of Cycle World.

Someday I'd love to get my hands on one of these engines.