This is a followup to a previous post. Thanks for reminding me Shep.

The CB550 tank was a mess of rust and varnish inside so I used a mild acid called vinegar to clean it out. The vinegar sat in the tank for about 5 days and was shaken now and then to agitate it.

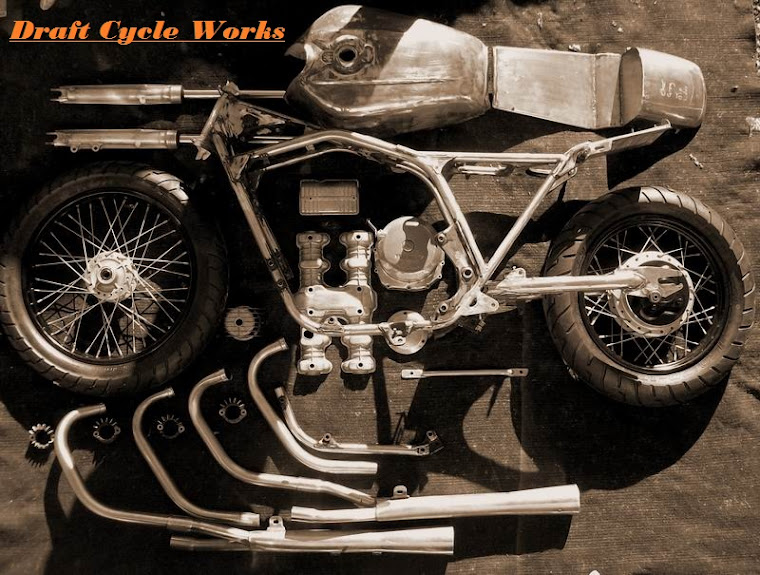

When I poured it out, it was yellow, gritty, and filled with fine chunks of rust and varnish. The inside of the tank looked like bare metal with brazing spots. It was quite clean and was enjoying a bit of flash rusting before I could take a good picture. Unfortunately, I wasn't able to get any before pictures, and the after pictures don't do it justice. There is an after picture below.

So does vinegar work to derust a tank?

Yes. I would say so.

Is it easier to deal with than say, MEK?

Umm. I shouldn't have to answer that, but yes. Yes it is. Vinegar doesn't cause skeletal birth defects. Also, it's easier to dispose.

Do you really have to wait 5 days for it to clean the tank?

I don't know. I didn't have time to check it for a few days but based on the results, I'd bet it would do a fantastic job in 48 hours.

Was it easy?

Filling something up and forgetting about it for a while is pretty darn easy. I can forget things without even trying.